-

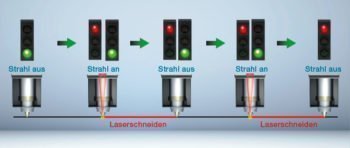

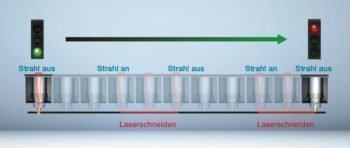

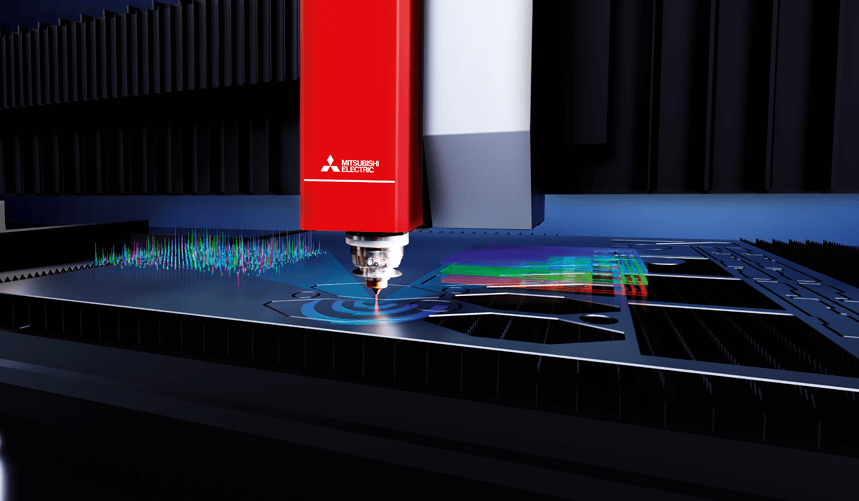

The green wave for your laser

is called F-CUT!

F-CUT – more output at lower costs! Continuous movement of the processing head without stopping at the beginning or end of a contour – only the laser beam is switched on and off. This function is made possible by fast direct communication between laser control and axis control via MHC-L (Mitsubishi Electric High-speed Control for Lasers).

The laser beam can thus be activated or deactivated within one microsecond.

With F-CUT you achieve a significantly shorter machining time (higher part output) and thus reduced costs per part.

-

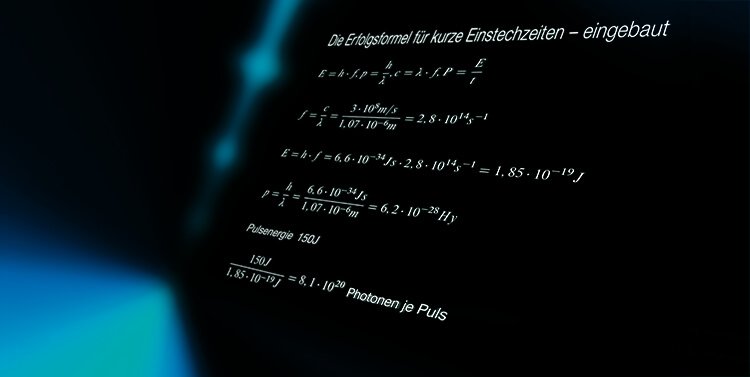

Billions extra photons.

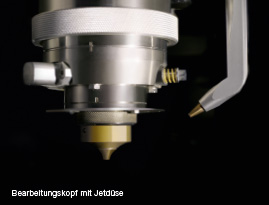

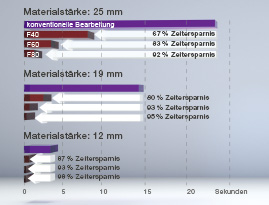

Up to 98 % shorter piercing time for mild steel!

Reduction of piercing times for medium and thick sheet thicknesses

The skilful combination of high-energy pulse peaks and a jet nozzle can lead to piercing times being reduced by up to 98 %. In recent years, it has been possible to increase the thickness of the material for which high-peak piercing can be used from 8 to 25 mm. -

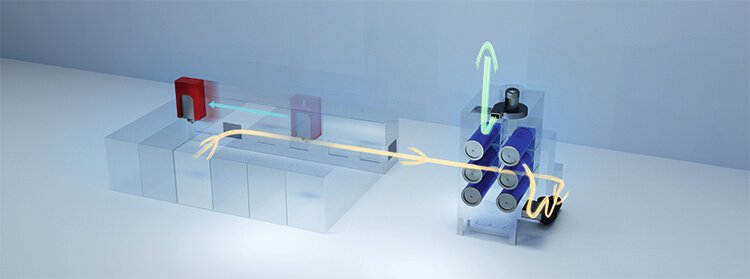

Fiber

-

CrossFlow

-

Operator health and the environment benefit

with Mitsubishi Electric!

BETTER TO EXHAUST FUMES WITH TARGETED CONTROL OF THE INDIVIDUAL AREA THAT REALLY MATTERS.

The fumes arising during the cutting process are exhausted reliably and, depending on the position of the processing head, locally and passed through a filter system with a purity rate of 99.999 % (minimum particle size 0.5 µm) – and with minimal maintenance effort. The outcome is clean air – safe for the operator and the environment. The outcome is clean air – safe for the operator and the environment. -

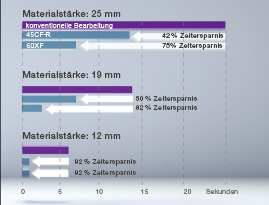

PREVENTING COLLISIONS: PROCESSING HEAD RETRACTS TO PREVENT COLLISIONS

At the start of every program, the Z axis rises into its topmost position before the processing head moves into its starting position. This reduces the collision risk and supports reliable operation – irrespective of the operator’s level of knowledge.

-

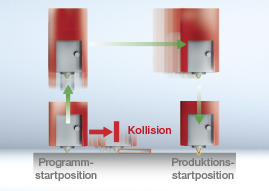

SAFE NIGHT OPERATION: THE “NIGHT MODE”

Night Mode can be activated manually or automatically at a previously set time. The Night Mode adjusts the motion sequence of the processing head and slows down the pallet in- and outfeed. Night Mode thus reduces noise emissions and the risk of collision. This means less annoyance of the neighbourhood and less downtime.

-

IN CASE ANYTHING SHOULD GO WRONG: THERE’S STILL THE MAGNETIC DAMAGE REDUCTION MECHANISM

The processing head held magnetically in position can be returned to its original position within seconds after a collision. This not only minimizes the risk of components being damaged by collisions, but also reduces the need for nozzle centering after an unforeseen touch.

-

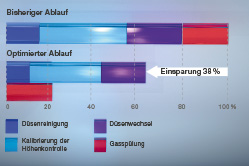

Optimisation of unproductive times?

A standard feature that pays off.

-

1. SCAN BAR CODE

-

2. PRESS START

Action! -

Self-Check

All the chief components of the laser cutting system are constantly monitored. And all monitored parameters are neatly displayed on the main screen.

-

Active Control

During the cutting process it is possible to steplessly adjust both the focus position and cutting speed.

-

Built-in expertise.

Giving you all the help you need.

-

REMAINING TIME DISPLAY

Displays the time remaining until the end of the program. So you can see at any time when the cutting job is finished. This way everything runs smoothly.

-

TIME FORECAST

Before the program starts, the time forecast indicates the expected processing time for the program. This way the operator can plan flexibly at all times.

-

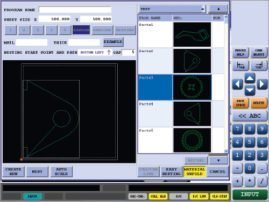

RAPID PRODUCTION OF EXTRA PARTS

Should extra parts be needed at any time, these can be produced with just a few mouse-clicks at the control. Even simple nesting is possible.

-

Cut-off function

Easily cut offcuts into several pierces by using the Offcut Cutting screen.

-

Automatic nozzle changer

Automatic nozzle changer with 9 slots

9 nozzle positions with dedicated NC screen.

The nozzle changer will change and calibrate nozzles automatically when changing cutting conditions or workpieces.

In combination with the optional “AI assistance and NozzleMonitor” it can replace damaged nozzles to allow stable unmanned processing without cutting failures due to damaged nozzles.

The nozzle management screen on the HMI allows a good overview about the condition of every nozzle (i. e. nozzle type, remaining time, nozzle condition). Additional paramters (i. e. usable time, used time, next monitor time, laser picture of the nozzle) can be checked, set or changed.

-

Automatic nozzle changer with 21 slots

21 nozzle positions with dedicated NC screen.

The nozzle changer will change and calibrate nozzles automatically when changing cutting conditions or workpieces.

In combination with the optional “AI assistance and NozzleMonitor” it can replace damaged nozzles to allow stable unmanned processing without cutting failures due to damaged nozzles.

The nozzle management screen on the HMI allows a good overview about the condition of every nozzle (i. e. nozzle type, remaining time, nozzle condition). Additional paramters (i. e. usable time, used time, next monitor time, laser picture of the nozzle) can be checked, set or changed.

-

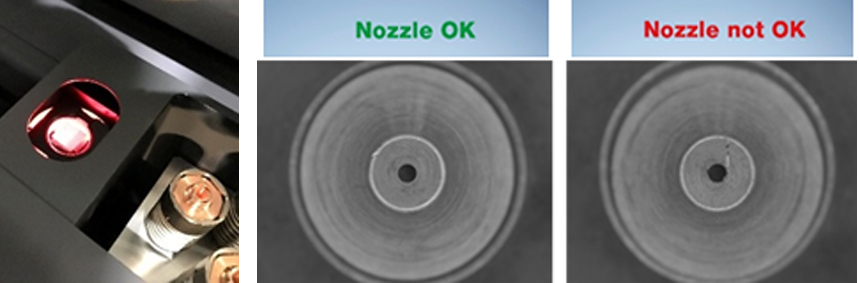

AI NozzleMonitor

- AI NozzleMonitor requires AI assistance and an autom. nozzle changer

- The NozzleMonitor takes pictures of the nozzles to check the nozzle condition.

- A check of the nozzle condition takes place after a set cutting time and can also be requested by AI Assistance (option) as soon as a cutting failure has been detected.

- The AI software automatically identifies if the nozzle still is in a good condition or if it is damaged.

- In the case of a damaged nozzle the software automatically checks if there is any spare nozzle of the requested type in the nozzle changer (option). If yes, it automatically changes the nozzle. If not, it will stop the process and send an error message to the operator.

-

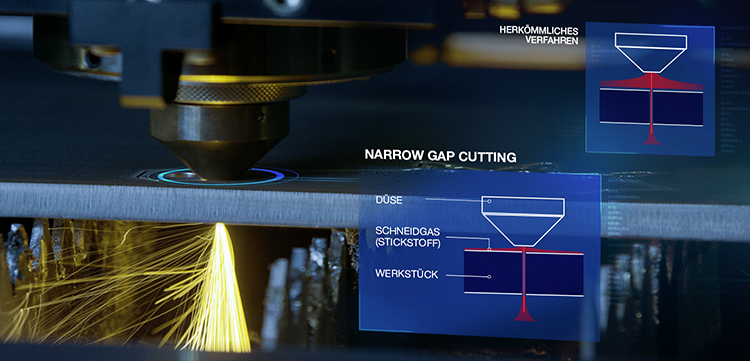

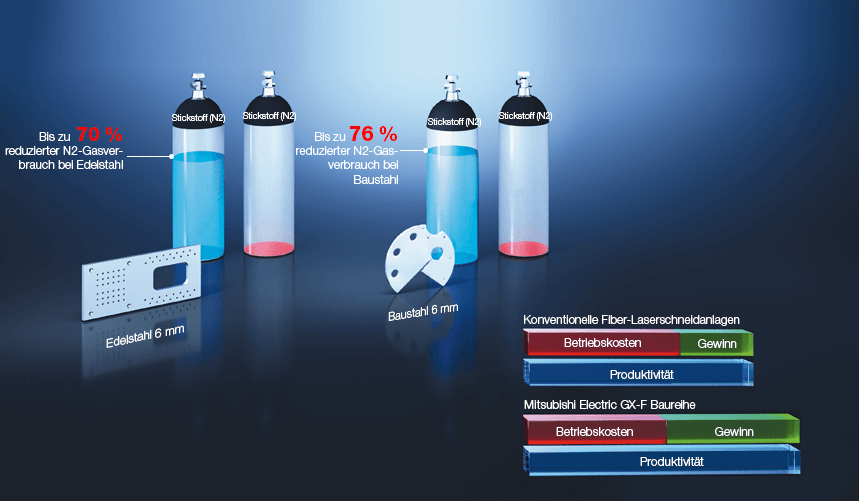

AGR-eco

AGR-eco increases the profit by reducing the costs and increasing the output. Es kann die Betriebskosten senken, indem es den Verbrauch des Schneidgases Stickstoff (N2) um bis zu 76 % reduziert, während es die Produktivität um bis zu 26 % steigert. This economical optimization is mainly achieved by Mitsubishi Electric’s original nitrogen gas flow technology and the faster communication by the AI-assisted D-CUBES CNC control but also due to shorter piercing times and higher cutting speeds due to the high beam quality of Mitsubishi Electric’s own fiber laser source. The benefits are available without the disadvantage of any nozzle touching the material surface – meaning no scratches on the surface – and working with material from 1 to 25 mm thickness.

- Up to 76 % nitrogen (N2) gas reduction with mild steel (8 kW fiber laser source).

- Up to 70 % nitrogen (N2) gas reduction with stainless steel (8 kW fiber laser source).

- Up to 26 % productivity increase (8 kW fiber laser source).

- No scratches on the material surface (the nozzle is not touching the material surface).

- Working with material (normally to be cut with nitrogen (N2)) 1 to 25 mm thick.

-

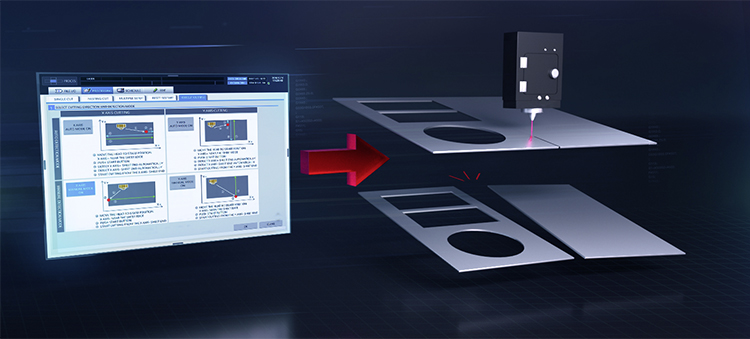

MEL’S AR - augmented reality technology

For increasing the remnant sheet utilization and to reduce setup time the operator friendly function “MEL’S AR” – augmented reality – was designed. After placing the remnant sheet somewhere within the working area a virtual top view photo can get created by pressing a button on the D-CUBES control panel. Afterwards single parts or complete nestings can be placed onto the remnant sheet. This makes sure that the parts really fit onto the designated remnant sheet.

- MEL’S AR-function incl. two cameras inside the machine.

- Higher remnant sheet utilization.

Easy virtual placing of the parts by drag and drop.

Products

4050 x 2060 mm

4050 x 2060 mm 4 / 6 / 8 / 12 kW

4 / 6 / 8 / 12 kW

3050 x 1525 mm

3050 x 1525 mm 4 / 6 / 8 / 12 kW

4 / 6 / 8 / 12 kW

3050 x 1525 mm

3050 x 1525 mm 4,5 / 6 kW

4,5 / 6 kW